Our Commitment to Sustainable Packaging

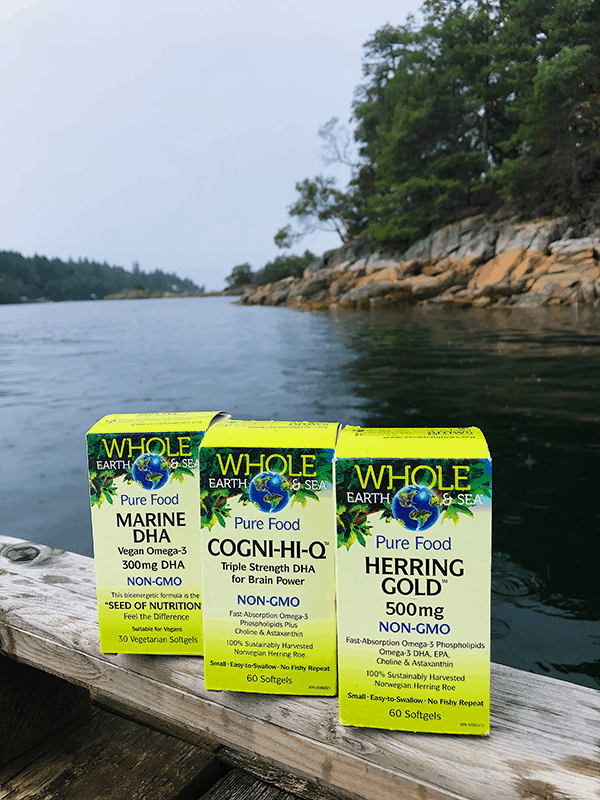

At Whole Earth & Sea, we know that your health and the environment go hand in hand. That’s why we’re devoted to producing sustainable supplements and natural health products through and through. Along with sourcing environmentally friendly ingredients, we use quality packaging material derived from glass and post-consumer recycled plastic.

Glass Packaging

The care that goes into producing high-quality, environmentally friendly supplements, such as Pure Food Marine Algae-3™ – a vegan omega-3 EPA & DHA formula – and Pure Food Super Mushroom, is applied to the whole product, including the packaging. Glass is an environmentally sound material, which is why the majority of Whole Earth & Sea products are packaged in glass bottles with an outer box made from 100% recycled material.

Glass is sustainable

Glass is sustainable and fully recyclable. You can put our glass bottles into your recycling bin for curbside pick-up or drop them off at your local recycling depot.

Glass can be recycled over and over in a closed loop, from recovery of glass waste to reproduction as a new bottle, without compromising its quality. Recycled glass can be used in place of raw material up to 95% of the time. This helps lower emissions because recycling glass is less energy intensive than making it new.[1]

Glass reduces waste

Glass is an inert material, meaning it does not react chemically with its contents and helps preserve their quality. Glass that is tinted amber also keeps vitamins and supplements fresh by protecting them from ultraviolet light damage.[2] Glass packaging can help reduce the waste of supplements that are prone to oxidation or other forms of spoilage.

As an inert and “generally recognized as safe” or “GRAS” material, regular glass does not contribute toxic residues to its contents or to our soil and waterways.[1]

The challenge with glass

The biggest challenge with glass packaging is that it can be heavier than other materials. For packaging larger-sized products, it can be more sustainable to use other forms of recycled material, such as post-consumer recycled plastic.

Post-Consumer Recycled Plastic

Don’t be fooled by the packaging used for our delicious Fermented Organic Protein & Greens and Fermented Organic Greens powders. This is no ordinary plastic! Our bottles are made from post-consumer recycled (PCR) plastic. There’s a big difference between PCR plastic and regular plastic.

What is PCR plastic?

Our PCR bottles contain EcoPrime™, a patented plastic made from curbside recycled food and beverage packaging – HDPE (High-Density Polyethylene) plastic. It is cleaned and sterilized with a unique, patented process using heat and air to eliminate contaminants without the use of chemicals. Once clean, it is melted and formed into PCR plastic bottles and other containers.

PCR plastic vs. “virgin” plastic

In contrast to PCR bottles, making bottles from “virgin” HDPE plastic would consume 88% more energy and produce 71% more emissions.[3] This is because new plastic is made by refining ethylene extracted from either natural gas or crude oil, two non-renewable resources. Plastic production involves steps of extreme heating and cooling, followed by the addition of solvents, additives, and other chemicals that help transform ethylene into plastic polymers.[4]

By using PCR bottles, we help reduce the demand for new plastic manufacturing.

Safe and recyclable

The EcoPrime plastic used for our PCR bottles has the same safety standards as conventional HDPE (#2) and contains no BPAs or heavy metals.

Our PCR plastic bottles can also be recycled back into circulation as plastic resin to make new containers. This helps keep the bottles from going into landfills and allows new material to be created without extracting more resources from the earth.

Our Commitment to Sustainable Packaging

At Whole Earth & Sea, we are continuously working to reduce our footprint and help consumers tread more lightly on Earth. By packaging our supplements in glass and post-consumer recycled material, we are reducing waste and unnecessary use of energy. After all, why take more of Earth’s precious resources when we already have what we need right in front of us?

References:

(1) Glass Packaging Institute. Glass recycling facts. Available from: http://www.gpi.org/recycling/glass-recycling-facts [Accessed 8th January 2020].

(2) Coles R, McDowell D, Kirwan MJ. Food packaging technology. New York: CRC Press LLC; 2013.

(3) Franklin Associates, A division of Eastern Research Group (ERG). Life cycle impacts for postconsumer recycled resins: PET, HDPE, and PP. APR. December 2018.

(4) American Chemistry Council. How plastics are made. Available from: https://plastics.americanchemistry.com/How-Plastics-Are-Made/ [Accessed 8th January 2020].

.png)